The Uncoder

An Automatic Universal CTCSS

Tone Encoder/Decoder

Introduction

I hate to let any piece of equipment go to waste, but what do you do with those old 2-Meter FM rigs that don’t have any CTCSS tone capability? Well, you add it of course! While ‘big knob’ tone encoders have been available from several sources, their downside has been having to know the tone of the repeater you would like to use and the need to turn the knob every time you change repeaters. Wouldn’t it be nice to have an add-on tone encoder, and decoder, that “sniffs” the PL from the repeater just like those fancy new rigs? Plus as an added convenience, and safety feature, remember what the tone was for each repeater! Imagine, not having to take your eyes off the road to rotate a knob just to change the PL! Now you can have all this and, as the man on the late night infomercials says, more with the Uncoder!

The details of a Universal Encoder/Decoder, or Uncoder for short, really started to gel when I decided to resurrect a couple of 2 meter rigs that had been laying around the shop, unused, for quite a while. One of the rigs was a Kenwood TS-700A all-mode base station transceiver and the other was a TR-7400A mobile that I wanted to be able to use with some of the local PL required repeaters. I wanted a device that was intuitive to use; just tune the transceiver to the repeater and let the Uncoder worry about the tone setup. The best solution would be a tone encoder / decoder that could detect the frequency that I was operating on and set the tone frequencies appropriately. Once I had given the Uncoder the CTCSS tone information for a particular frequency, it should be able to remember the setting and automatically set up the tone info as I tuned my radio to various repeaters. To accomplish this task, the Uncoder needed to incorporate a frequency counter, along with the tone encoding / decoding and the appropriate microcontroller circuitry.

About the Circuit

The

selection of a microcontroller chip to base a design on is an important

decision in working out a circuit. The microcontroller needs to have enough

memory, I/O pins, and system resources to support the work it needs to perform.

Although there are many fine microcontroller products available in the market,

I have always been a fan of Atmels’ line of flash programmable devices. One

great feature of many of the processors in Atmels’ line of microcontrollers is

the ability to serially program the flash code memory space in the chip while

it is installed in the circuit. With this feature you can make changes in the

program and then download the new code to the microcontroller without removing

or changing any of the components on the circuit board. This is a great

advantage while debugging your code. The device I chose for this project was

the ATmega8 microcontroller. The Atmega8 incorporates 8K of program flash, 512

bytes of EEPROM, to hold the frequency tone lists, 1K of RAM, several internal

counter / timers with input capture facilities as well as serial pots and even

an 8 channel A/D converter. Although I didn’t use all of the Atmega8s features,

some really help simplify the design of the Uncoder.

The

ATmega8s input capture feature, along with its associated timer, allows the

microcontroller to accurately measure the period of a waveform. An input

transition on the Input Capture Pin, U2 pin 12, causes the microcontroller to

record the value one of its internal counters which is being continuously

incremented by the processors crystal controlled clock.

This

action performs most of the functions of the frequency counter portion of the

Uncoder. RF, generated by the transceiver local oscillator, is brought into the

Uncoder at spring pin P1. The local oscillator signal is coupled to the input,

pin 8, of IC U7 a LMX1501 Frequency Synthesizer chip. Although the LMX1501 is

intended to be used as a frequency generation device in the Uncoder U7 is used

to amplify the local oscillator and divide the frequency down to a point where

its period can be measured by the microcontrollers input capture circuitry.

Fig. 1 Uncoder Schematic

The

Uncoder uses a tone encoder / decoder chip whose intended use was in FRS and

GMRS radio equipment. The CMX808A, U6, incorporates a CTCSS tone generator, a

fast acting tone detector and various signal-conditioning components. The

CMX808A can detect and decode a sub-audible tone in 150 mS. The highly

integrated features of this device help keep the component count down in the

Uncoder. Interface to the CMX808A is made through a clocked serial interface.

The required 4MHz clock for U6 is borrowed from the microcontrollers crystal

oscillator via C22. The output tone from U6 is routed to the tone level pot,

R26, and then is buffered and filtered by op-amp U5 and its associated circuitry.

I

used a 4 digit seven segment LED display on this project. The display is

multiplexed, which means that each display digit is briefly illuminated one

digit at a time, with the full 4 digit indication being scanned across the LED

device. Since the digits are scanned quickly, about 30 times a second, all of

the digits appear to be illuminated at once. This display multiplexing scheme

affords a simplified circuit because the displays segments are connected in

parallel and require only a single drive. The segment drive is generated by U3,

an 8 output shift register. The choice of a shift register for an output port

was made for economy. With the shift register you can generate 8 outputs from a

single 16 pin chip while employing only 3 I/O connections to the processor.

Since other devices in the design share the clock and data lines there is only

1 extra output line, OLD an output load strobe, required from the processor to

generate the 8 segment outputs for the display. The LED display also uses 5

digit select lines to select each of the 4 display digits plus a digit select

for the mode displays. These digit select lines are generated by the

microcontroller and buffered by transistors Q2, 3, 5 and 6.

The

Uncoder uses microcontroller I/O pins for the 3 push buttons, the rotary

encoder, the Xmit and Off Hook interface inputs and a Tone Detect output that

is buffered by transistor Q4. Diodes D1 and D2 are used to block voltages

greater the Vcc, +5 VDC, on the Xmit and Off Hook interface inputs. Connector

J1 allows an inexpensive programmer to be plugged into the Uncoder for program

update. Connector J2, an 8 position modular jack, is used for connection of

most of the Uncoders signals to the host transceiver. I chose the modular jack

because of their easy availability, these jacks are commonly used for CAT5

network wiring.

Construction

The components used in the Uncoder required this to be a surface mount project. Although many people seem to be uncertain about their ability to build projects that employ surface mount components, the fact is that it is easier to use these devices. This, coupled with the fact that through hole parts are becoming more difficult to obtain, requires the modern ham to spend the few hours of time learning surface mount construction techniques. Although it isn’t the intention of this article to provide a step by step tutorial in surface mount construction techniques, I will provide a few pointers that I feel may be helpful in constructing the Uncoder.

Surface Mount

Assembly Notes:

1.

A

mentor of mine once told me that cleanliness is next to godliness, except in

soldering where cleanliness is next to nothing. This particularly holds true

with soldering surface mount components. Obtain a variable temperature

soldering station, and make sure you keep the tip clean and tinned. You will

definitely need to have a wet sponge to wipe the tip on regularly. I also

suggest regularly dipping the tip of your iron in tinning flux. I put a

teaspoon or so of Oatey # 95 tinning

flux in a bottle cap and dip the soldering iron tip into it when it get dry.

The Oatey product is available at many hardware stores.

2.

Apply

a small quantity of rosin paste flux, Kester SP-44 for example, to the circuit

board pads before placing the components. Don’t use too much and try to keep it

on the solder pads. If you use too much you will just have more to clean up

after assembly.

3.

Install

the surface mount components first. That way your board will sit flat on your

workbench.

4.

When

soldering the components, apply the soldering iron and solder to the solder

pad, not the component lead. This will help to keep the component from moving.

5.

Tack

solder one lead of ICs then check to make certain that the rest of the

component leads are still centered over their PC pads before completely soldering

all of the leads. It is a lot easier to reposition a component when only a

single lead is soldered.

6.

When

you need to install ICs with very close leads, like the CMX808A, a technique

that works quite well is to:

A.

Apply

a fair amount of solder to the tip of your iron.

B.

Dip

the tip into the tinning flux.

C.

Draw

the wetted bead of solder across the PC board / component leads.

This is a kind of poor mans wave soldering. If you end up with bridged pads, clean the soldering iron tip on your sponge, dip it into the tinning flux, and then try to draw the solder from the bridged pads with the wetted iron. If you need to, you can always use some solder wick to remove a solder bridge. If you are out of solder wick, just remove and use some of the braid from a piece of coax.

7. Clean the flux residue from your board with a commercial flux remover or alcohol. Don’t use rubbing alcohol, it’s mostly water and won’t do a very good job.

8. Always carefully inspect your work after you complete the assembly. Use a strong lamp and a magnifier if needed. Sometimes it is easier to inspect a board if you shine the lamp through the board from the backside.

Uncoder Assembly Notes:

1. The three push button switches need to be mounted 1/16 of an inch above the topside of the PC board so that they will extend above the sheet metal front panel. Use the small PC board spacer between the switches and the main PC board to accomplish this

2. Note that pin 1 on all of the ICs is located closest to the reference designator “U” silk-screened on the PC board for that IC.

3. Make sure that the polarized caps and diodes are oriented properly. Double-check their orientation with the assembly drawing before soldering these components.

4. C1, the 1000uF/16V capacitor is mounted on the backside of the board and parallel to it so as not to extend above the connector J2. Study the assembled Uncoder picture to ascertain this orientation before soldering C1 into the circuit.

5. Make sure you properly orient the display in the PC board before soldering. The decimal points are closest to the J1 connector.

6. The RFIN connection point, and the associated ground lead located to its right, is made to accept a solderless spring pin. Install these pins with the open side of the pin on the same side of the board as the silk-screened markings. Carefully solder these pins in so that you don’t fill the open side with solder. These solderless spring pins are designed to accept a solid or tinned 24-28-gauge wire lead.

7. For normal operation, install solder jumper JP2. This connects interface connector pin 8 to signal ground.

8. Generally I make the interface cable, that mates with J2, with a 3 pair shielded cable, for the audio connections, a twisted 3 wire cable for V+, the xmit and hook switches, and a 22 gauge power ground lead. The standard cable configuration is indicated on the schematic. These wires are all crimped into a standard RJ-45 plug and then glued to form a strain relief.

9. You can either purchase a preprogrammed microcontroller or program this device in circuit. If you decide to program the device in circuit, there are several sources for the programming cable and associated software. The hardware required to program the Uncoder via a PCs parallel (printer) port is shown below. One good source for the programmer software is:

http://www.lancos.com/prog.html

Fig. 2 Parallel Port Adapter for Uncoder

Microcontroller Programming

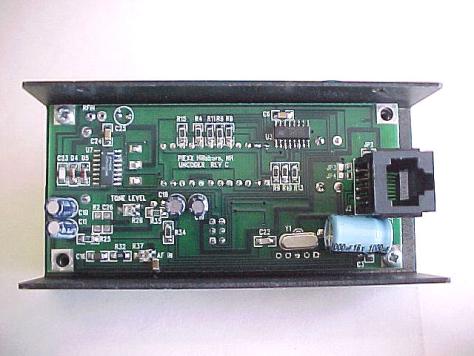

Fig. 3 Bottom Side of Assembled Uncoder Board

Fig. 4 Top

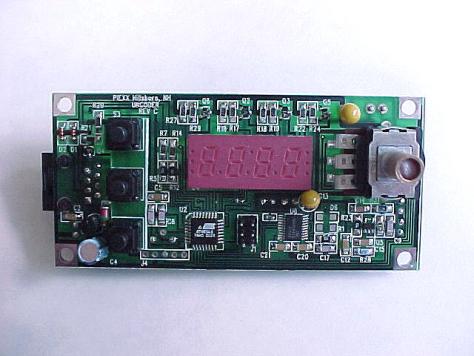

Side of Assembled Uncoder Board

Connection to Transceiver

The pin out for J2, the modular 8 pin interface connector is as follows:

1. +12 VDC In

2. Audio In

3. Xmit

4. Audio Out

5. Hook Switch

6. Tone Out

7. Power Ground

8. Signal Ground.

Depending on the intended use, and the locations of solder jumpers on the board, you may not need to connect all of the signals. For most of the installations that I have done, I have connected the Uncoder to provide both transmit and receive CTCSS functionality.

The power required for the Uncoder is +9 to +15 VDC at approximately 50 mA. The power lead, pin 1 of J2 should be connected to a convenient switched supply within your transceiver. The return connection for the power is on J2 pin 7.

In order for the Uncoder to operate in a tone squelch mode, it needs to sample the detected audio and provide a way to disable the audio path in the squelched condition. The Uncoder provides an open collector transistor output that can be connected into your transceivers circuitry to enable or disable the audio path. An easier way to take care of both the tone input and squelch requirements is to connect the Uncoders audio in, J2 pin 2 and audio out, J2 pin 4, in series with the hot lead of your rigs volume pot. The CMX808A chip has an audio switch in line with its audio path, and this switch is deactivated by the Uncoder firmware when the tone squelch is activated and the correct tone signal is not seen. The connection in a typical transceiver is outlined in the schematic shown in figure 5. If you have no need for tone squelch, simply connect J2 pin 2 to the high side of the volume control and leave J2 pin 4 unconnected. If you do not connect the audio in signal to the Uncoder, the device will not be able to detect and report the CTCSS tone being used with its FIND mode.

Fig. 5 Uncoder Receive Audio Connection

The tone output is available from the Uncoder on connector J2 pin 6. If your rig has a connection point for a tone generator, you should connect the tone out to it. Otherwise, connect J2 pin 6 to a point in the transceivers close to the modulator and past the mic conditioning circuitry. The tone output level from the Uncoder can be adjusted to about 1V RMS if necessary. Often a good point to inject the tone output is the high side of the deviation control. If you must connect the tone output to a point in the transceiver near the mic input you may need to install a series resistor in line with it to reduce the tone signal level so that it won’t swamp out the modulator

The Uncoder needs to be able to detect when your transceiver switches to the transmit mode. P2 pin 3, the Xmit detect line, should be connected to either the PTT line on your Mic plug, the transmit indicator light or a switched Xmit power connection. Don’t worry about the polarity of the signal, it can be switched in one of the setup menus.

J2 pin 5, hook switch, is an input to the Uncoder indicating that the mic has been taken out of its holder. If you have a mic holder that is switched connect this line to it and when you unhook the mic the tone squelch will be defeated allowing you to hear the channels activity.

In order for the Uncoder to work in the automatic mode, it must be able to determine the frequency that your transceiver is tuned to. Frequency detection is accomplished by installing a shielded lead connection from the RFIN connection point, on the Uncoder, to the receive local oscillator output of your transceiver. Most transceivers have a shielded cable running from a buffered VCO output on their synthesizer (or PLL) circuit board to the receiver first mixer input. This usually makes for a convenient connection point to the Uncoders RFIN frequency counter input. With some transceivers the local oscillator is sufficiently ‘hot’ to be picked up by simply positioning the center lead of a coax connected to the Uncoders RFIN input in the vicinity of the oscillator. If this method is employed, be sure to cable tie the shield lead in place so that its sense lead won’t shift position during normal operation of the transceiver.

It is a good idea to make your connection to the transceiver as short and direct as possible.

Note: avoid excessively long cable lengths for all connections.

The Uncoder Installed on a TS-700A

Set up

After

you have installed the Uncoder on your transceiver, and applied power, the display

should light up and it will show different information depending on how the

Uncoder has been set up. If the display shows:

CrC then the Uncoders channel / setup memory is undefined and must be

reset. Resetting the Uncoders memory is performed by simultaneously pressing,

and then releasing, all three of the front panels buttons (press the XMIT

button first, and then while holding it simultaneously press and hold the RCV and AUTO buttons). When the display

shows CLr release the buttons. This procedure clears the

channel memory as well as resets the setup parameters to the default state.

You

will need to adjust the setup parameters to match your hardware configuration.

To enter the setup mode, press and hold the XMIT button, for about ½ second,

until the first setup parameter appears. Once in the setup mode, you can cycle

through the various setup parameters by pressing the XMIT button. Each time you press

the XMIT button, the program cycles to the next setup

parameter. Rotating the encoder knob will change the value of a parameter. All

parameters, except the A (audio level) parameter, can be set to one of four

possible states, 0, 1, L

or h. The audio level parameter can

be set to a value between 0 and 31. The setup parameters are defined as

follows:

td – Tone Detect output state.

0 – If the td parameter is set to 0, the tone detect output will be set to a steady state low value, that is transistor Q4 will always be turned on.

1 – (default) The tone detect output will be set to a steady state high value, that is transistor Q4 will always be turned off.

L – The tone detect output will be go to a low state, Q4 on, if the tone squelch is enabled and the correct CTCSS tone is detected.

h – The tone detect output will be go to a high state, Q4 off, if the tone squelch is enabled and the correct CTCSS tone is detected.

tP – Transmit Detect input

polarity.

0 – If the tP parameter is set to 0, the input is ignored. The CTCSS tone, if selected, will appear on J2 pin 6.

1 – If the tP parameter is set to 0, the input is ignored. The CTCSS tone, if selected, will appear on J2 pin 6.

L – (default) The Uncoder will go to the transmit mode when the Xmit signal on J2 pin 3 goes to a low state, less than .5 VDC.

h – The Uncoder will go to the transmit mode when the Xmit signal on J2 pin 3 goes to a high state, greater than 3 VDC.

When the Uncoder goes into the Xmit mode, the CTCSS tone that is selected will be output on J2 pin 6 and the automatic frequency scanning algorithm will be suspended if the Auto mode is enabled.

hP – Hook Switch input

polarity.

0,1 – If the hP parameter is set to 0 or 1, the input is ignored.

L – The off hook condition is detected when the Hook Switch signal on J2 pin 5 goes to a low state, less than .5 VDC.

h – (default) The hook condition is detected when the Hook Switch signal on J2 pin 5 goes to a high state, greater than 3 VDC.

When the Uncoder detects the off hook state, the tone squelch, if selected, will be disabled. This allows you to hear, when you pick up the mic, all stations operating on a frequency even if they aren’t using a CTCSS tone.

A- Audio Level.

In addition to the CMX808As audio switch, it also has a level control in the audio path. When the Uncoders tone squelch is open, the audio level, as seen at J2 pin 4, is set according to the A value. An A value of 0 effectively turns off the audio channel, the maximum audio is achieved when A is set to 31.

PU – Power Up state.

1 – If the PU parameter is set to 1, the Uncoder will enter the Automatic mode when it is powered up. Any other PU value will cause the Uncoder to power up in the normal Tone mode.

The default state of PU is 0.

SU – Set Up.

The Set Up parameter is not really a parameter setting but a way to access various calibration routines. Selecting a value with the knob and then entering the selected routine by pressing the RCV button enters the calibration routines. Depending on the value selected, there are four possible calibration routines that can be executed:

0- This routine shows the frequency that the Uncoder is currently detecting. The display will continuously update until the operator, again, presses the RCV button.

1- This routine calibrates the Uncoder frequency counter. For 2-meter operation, the receive frequency should be set for 146.520 MHz prior to selecting this calibration routine. After the calibration takes place the routine enters the frequency display mode and the display will continuously update until the operator, again, presses the RCV button.

This routine only calibrates the frequency counter. Since you normally would want to set the IF offset frequency before calibration, using the L routine is generally the more appropriate calibration routine to use.

L- This routine allows the operator to preset the IF frequency offset and then calibrates the Uncoder frequency counter. For 2-meter operation, the receive frequency must be set for 146.520 MHz prior to selecting this calibration routine. When this routine is entered, the IF frequency will be shown with the display cycling between the MHz digits and the KHz digits. By turning the knob, you can adjust the IF frequency offset to that of your transceiver. Once the IF offset is correctly set, press the RCV button to enter the value and continue with the calibration. After the calibration takes place the routine enters the frequency display mode and the display will continuously update until the operator, again, presses the RCV button.

H- The last calibration routine is used to set the receive audio level provided to the tone decoder chip. When this routine is selected the display will show a continuously updated 3 digit reading that is proportional to the audio level. Pot R37, marked AF IN on the bottom side of the Uncoder board, is used to adjust the audio level presented to the circuitry. Although the Uncoder is capable of working with a broad range of input levels, it is best to adjust R37 so that the LED display shows audio peaks in the 100-150 range. Generally the unsquelched receiver noise will provide the greatest readings on the display and should be used to make this adjustment.

You can exit the setup parameter menu by either pressing the RCV button or executing one of the four calibration routines.

Note: The xmit and receive tone values that were set when you entered the setup command, will be saved as the power up default ton values when you exit the setup command.

Operation

The Uncoder has two operating modes, normal and automatic. The automatic mode of operation is indicated by the right most decimal point, directly above the front panel silk screen marking “AUTO”, being illuminated. You can switch from the normal to the automatic mode by pressing the AUTO button. Switching from the auto mode to the normal mode is accomplished by pressing any of the buttons.

Normal Mode

Operation

In

the normal mode, you can manually set the transmit and receive tone frequencies

as well as using the Uncoders automatic tone detect feature to find the

frequency of a CTCSS tone being received. To set the transmit tone, press the XMIT button and then rotate the

knob to select the desired transmit CTCSS tone. If a transmit tone is selected,

the XMIT led indicator will light.

To

set the receive tone, press the RCV button and then rotate the

knob to select the desired receive CTCSS tone. If a receive tone is selected,

the RCV led indicator will light. Selecting a receive tone will enable the tone

squelch system, assuming that the off hook switch isn’t active, and the

transceivers audio will be muted. When a received tone, matching the tone that

the Uncoder is currently set to, is detected, the DET

LED will light and the tone squelch will open allowing you to hear the

broadcast.

To

find the tone being transmitted by a station, simultaneously press the XMIT and

RCV buttons. The RCV LED will blink indicating that the

Uncoder is operating in the FIND mode and is searching for a tone. If no tone

is detected the display will show four dashes in its numeric field. The dashes

will change to a valid tone frequency if a CTCSS tone is detected. You can exit

the FIND mode in two ways:

1.

If

you simultaneously press the XMIT and RCV buttons

the Uncoder will automatically set both the transmit and receive tones to the

detected tone frequency before exiting the FIND mode.

2.

Pressing

any other key will cause the Uncoder to exit the FIND mode without retention of

the detected tone.

Automatic Mode

Operation

In the automatic mode, the Uncoder samples the transceivers receive frequency and compare this to a user defined table of frequencies. If a match is detected the Uncoder will automatically set both the transmit and receive tones to those values retrieved from the table. In order for this process to proceed, the user must define the operating conditions for those frequencies that he wishes for the Uncoder to respond to.

To add a frequency to the Uncoders search list, simply tune your transceiver to the frequency of interest, set the transmit and receive tones as necessary for proper operation on that channel, and then save the information by simultaneously pressing the RCV and AUTO buttons. To remove a channel from the list, follow the same procedure but set both tones to OFF before saving the channel. If a channel is saved with the tones set to the OFF condition, its frequency is removed from the list. Similarly, a channels tone data can be modified by saving new tone information at the same frequency. This will cause the table entry for that frequency to be over written with the new data.

Once a frequency list is created, you can start automatic mode operation by pressing the AUTO button. In the automatic mode, AUTO LED will light and the last 4 digits of the frequency will show on the display. As you tune your transceiver you will see the XMIT and RCV LEDs change state as you tune through frequencies that you have entered in the channel list. If you key up your transceiver the automatic mode frequency scanning algorithm will be suspended until you return to the receive mode. Frequency scanning on transmit is suspended so that the Uncoder won’t see the transmit frequency as a different entry in the channel table and modify the toned data inappropriately.

Conclusion

I think it is a blast to figure out ways to improve on older equipment with current technology. The Uncoder lets you breathe some new life into some of your older, high quality FM equipment that has been shelved because of missing tone features. By incorporating a frequency counter, tone encoder / decoder and the appropriate microcontroller based glue, the Uncoder adds tone features to your older rig that perform as well or better than current production equipment. I hope that some of the design ideas employed in the Uncoder may act as a catalyst for other, future radio upgrade designs. The expanding microcontroller product lines, as well as the large quantity of LSI peripheral devices that appear every year, lend themselves nicely to the ham radio market and open the doors for a wide range of entrepreneurial endeavors.

Parts

List

Item Quantity Reference Part

______________________________________________

1 1 C1 1000uF/16V

2 10 C2,C3,C5,C6,C12,C14,C15,

C20,C21,C24 .1uF 1206

3 1 C4 100uF/16V

4 2 C8,C7 39pF

1206

5 5 C10,C11,C18,C19,C25 10uF/16V

6 1 C13 47uF/6v

7 2 C16,C30 1uF

1206

8 1 C9,C17 .001

1206

9 1 C22 39pF

1206

10 1 C23 22pF

1206

11 4 D1,D2,D4,D5 1N914

1206

12 1 D3 1N4001

SM

13 3 JP2,JP3,JP4 PJUMP

Solder jumper

14 1 J1 6

Pin Header

15 1 J2 8P8C

Modular Jack

16 2 P2,P1 Spring

Connector

17 5 Q2,Q3,Q4,Q5,Q6 2N4401 SOT23

18 5 R1,R5,R12,R23,R33 100K 1206

19 8 R4,R6,R8,R9,R10,R11,R13,

R15 470

1206

20 2 R7,R14 4.7K

21 10 R16,R17,R18,R19,R20,R21,

R22,R24,R27,R29 2.2K

22 1 R25 1K

23 2 R26,R37 POT47K

24 1 R28 68K

25 1 R30 330K

26 1 R31 82K

27 1 R32 47K

28 1 R34 1K

29 1 R36 Not

Used

30 3 S1,S2,S3 SWPCMNT

31 1 S4 RENCODE-CTS

32 1 U1 LM78L05

33 1 U2 AtMega8-16AC

34 1 U3 74HCT595D

35 1 U4 LTC8710HR

7 segment display

36 1 U5 LM321

37 1 U6 CMX808A

38 1 U7 LMX1501AM

39 1 Y1 4.00ECSZ

Crystal Parallel 22Pf

40 1 CAS1 Case

Assembly w/mounting Bracket

41 1 PCB Printed

Circuit Board

42 1 Cable Interface

cable assembly

The

following items are available from:

PIEXX

Co.

13 Main Street

PO

Box 123

Hillsboro, NH

03244

(603)

464-5411

Assembled and tested Uncoder

with Interface cable assembly $129

A complete set of parts

including the sheet metal case and interface cable $99

Semiconductor

kit including all ICs, transistors, diodes, LED display and pre programmed

microcontroller $37

PC board

kit including main and switch spacer PC boards $17

Switch

Kit including Rotary encoder & 3 push buttons $6.50

Painted

& silk-screened sheet metal case w/mounting bracket & LED lens $19

Interface

Cable assembly $10

Parallel Port Adapter for AtMega8 Programming $19

Links: